Problem Statement

Mechatronic or software-driven products or systems are typically composed of large numbers of immaterial (conceptual) and material artifacts which are created and used in one or several lifecycle phases. The artifacts are created using specific authoring systems, and need to be used across IT systems, disciplines and organizations. Hence, they are inputs and outputs of activities by different parties in the whole product lifecycle, collectively needed for collaboration on the product.

A Graph for Interrelated Artifacts

The activities with input and output artifacts which are related to mechatronic and lately so-called cyber-physical systems are covered by the standard ISO/IEC-15288. As it establishes a useful structure and widely accepted terms, it has been adopted for the CASCaDE initiative.

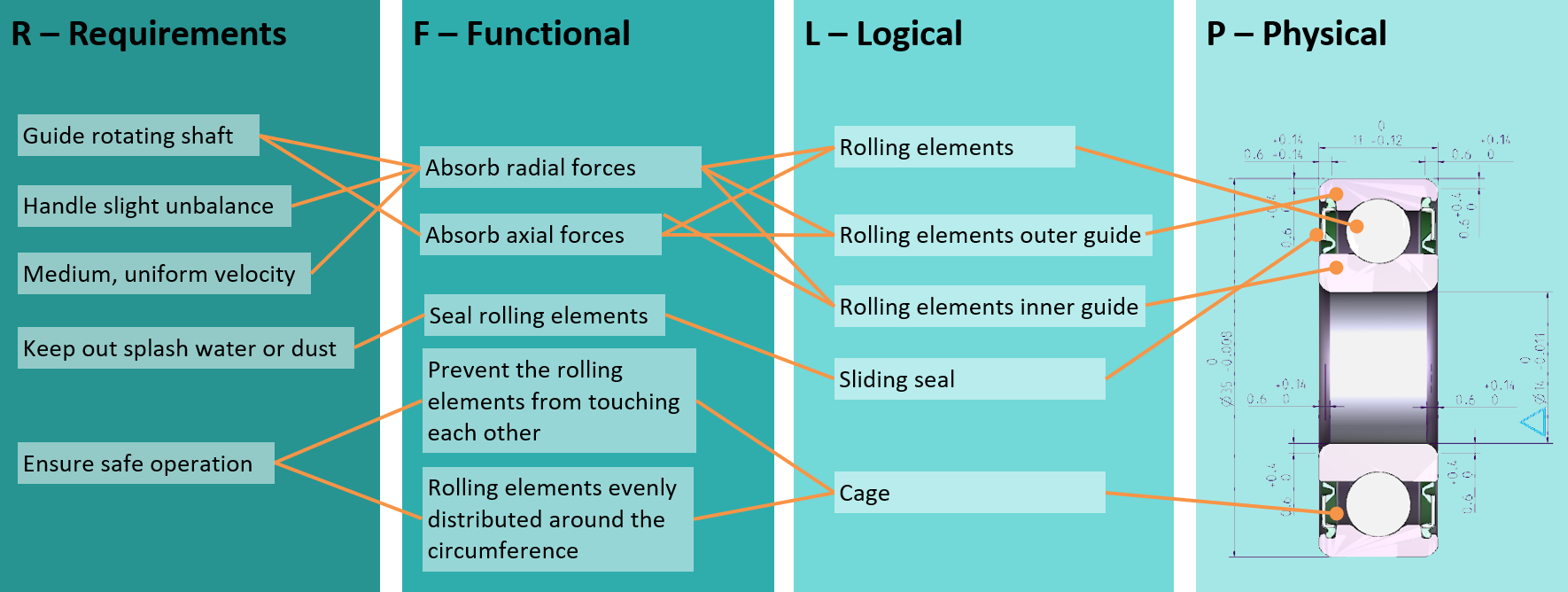

Fig.1: Example illustrating linked cross-domain product information. Source: Schaeffler AG.

Fig.1: Example illustrating linked cross-domain product information. Source: Schaeffler AG.

The example in Fig. 1 illustrates artifacts related to a ball bearing in four abstraction levels from requirement to physical system (following the RFLP design scheme by Dassault Systèmes Catia and others). The artifacts are interrelated, so that origin and consequences of a change can be traced. As pointed out above, the artifacts are produced in different development phases and by different teams using different tools, from elicitation of user needs to physical design for production, assembly, operation, repair and disposal. There is a need to put the artifacts of all participants and phases with their relations in a common context. By nature, product information is conceptually interlinked in many ways: An information may depend on another or certain information is used in different point in time. Most generally, there are at least three dimensions of relations:

- Abstraction: During development, according to the widely accepted RFLP method, a product is described by Requirement (R), Function (F), Logical Architecture (L) and Physical Architecture (P) as discussed above.

- Decomposition: Usually, a product has multiple components organized in a Bill-of-Material (BoM).

- Lifecycle: In different phases of a product’s life from conception to disposal, different information is of importance.

Generally speaking, the entities have attributes, such as title, description, etc. and are linked by causal, temporal or any other dependencies. A combination of a pair of entities with a relation is often called a statement composed of subject, predicate and object, or ‘Triple’. As such it is best represented by a graph of nodes and edges, commonly known as ‘Knowledge Graph’ or semantic net. By now, there are powerful technical solutions for Knowledge Graphs which can be applied with benefit.

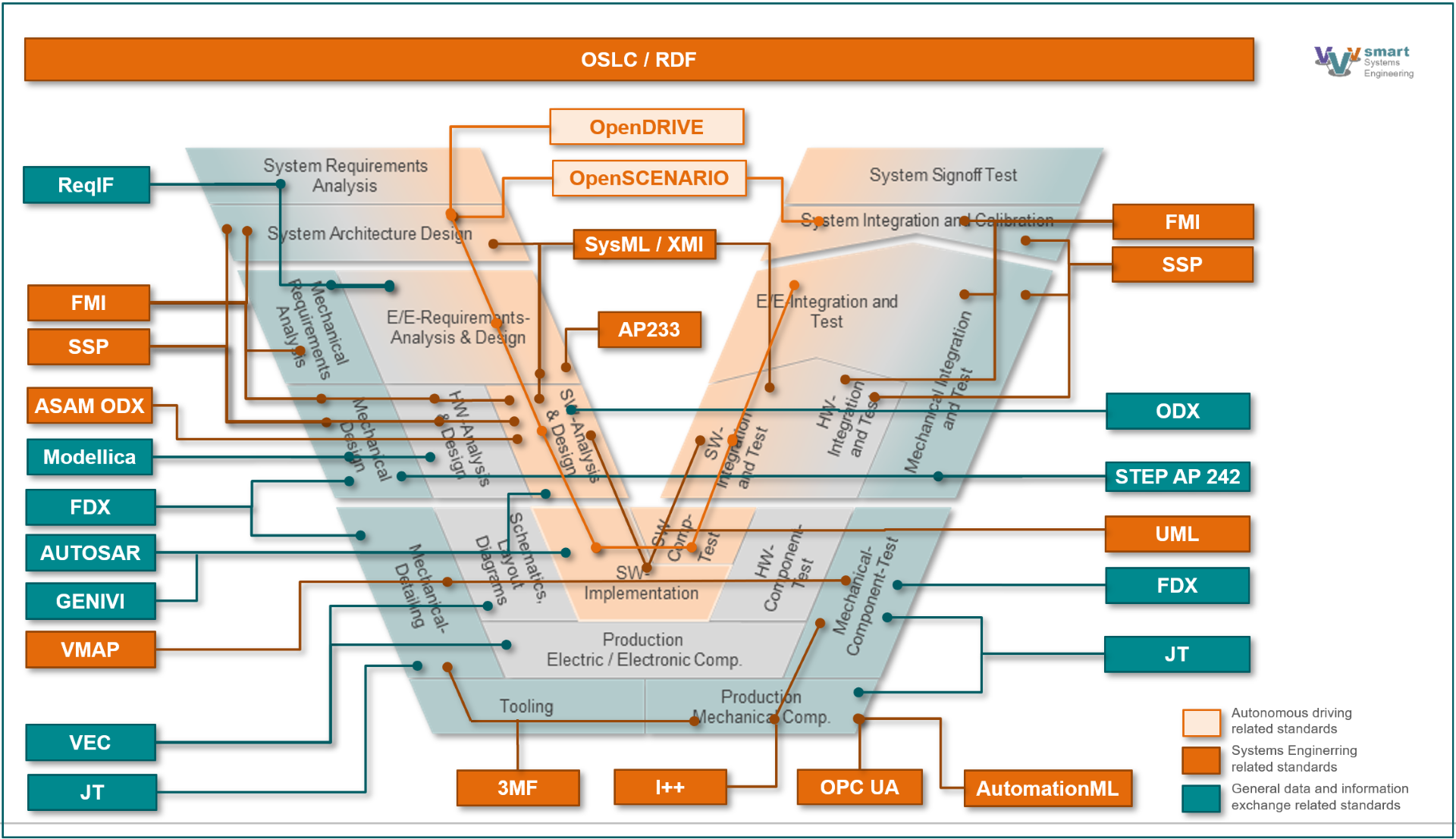

Fig.2: The V-Model of product development with some of the data formats used. Source: prostep ivip SmartSE Project Group Recommendation PSI 11 SmartSE V3.

Fig.2: The V-Model of product development with some of the data formats used. Source: prostep ivip SmartSE Project Group Recommendation PSI 11 SmartSE V3.

As product information is created in a variety of authoring systems and primarily stored in proprietary formats or databases, an overarching knowledge graph does not exist today. However, there is a variety of domain-specific data formats established in the industry that help bridge the gaps between different systems. Fig. 2 shows the product development process in more detail using the widely adopted V-Model (VDI-2206). Some of the data formats used in certain development tasks are depicted with colored boxes. Those data formats are targeted to best support their respective purpose and are backed by specialized tools with their own innovation cycle. It happens by nature that the same artifact appears in different data sets, making it difficult to propagate changes or even detect dependencies. Therefore, a translation of individual data sets and integration to an overarching Knowledge Graph is required.

Scenarios

Finally, there are different ways of interaction between organizations or, in terms of BPMN, collaborating participants. Generally speaking, four collaboration modes can be identified, which include the Boeing collaboration levels.

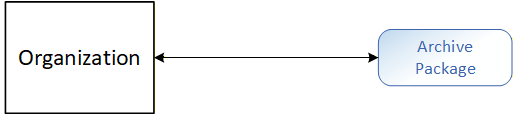

Longterm Archiving

Organizations primarily in regulated industries need to archive engineering data at least for the lifetime of a product, which may last many decades. Data requires a standardized format and ontology without the need for special software.

Fig.3: Longterm Archiving

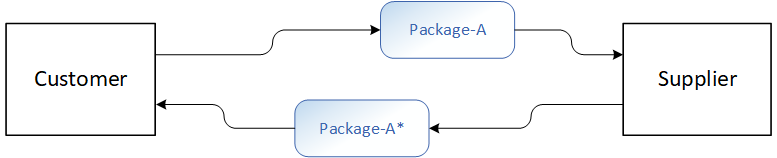

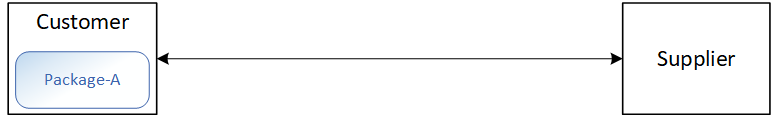

Collaboration Mode 1: Traditional File Transfer

Some organizations resist permitting access to their IT infrastructure to others and prefer to exchange selected information by file. In Collaboration Mode 1 partners operate on separate databases and synchronize their data periodically.

Fig.4: Collaboration Mode 1: Traditional File Transfer

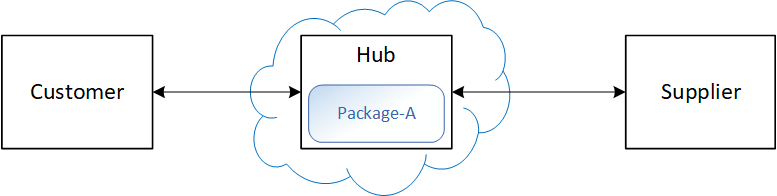

Collaboration Mode 2: Private Hub

In collaboration mode 2 one of the partners offers a common database for synchronous transaction processing. The remote partner receives permission to access the data of interest usually differentiated for create, read, update or delete operations.

Fig.5: Collaboration Mode 2: Private Hub

Collaboration Mode 3: Public Hub

Collaboration Mode 3 is very similar to the previous scenario, except that a common database operated by a third party („SaaS“) is used.

Fig.6: Collaboration Mode 2: Public Hub

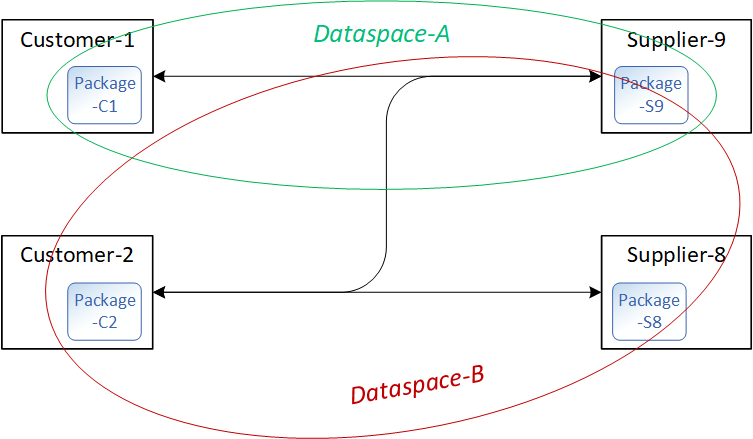

Collaboration Mode 4: Federated Dataspace

In the most advanced scenario, each partner retains full control of her or his data and permits others to access to data of interest. Dataspaces with distributed databases are created for transaction processing. A partner‘s package may be part of multiple dataspaces.

Fig.7: Collaboration Mode 4: Federated Dataspace

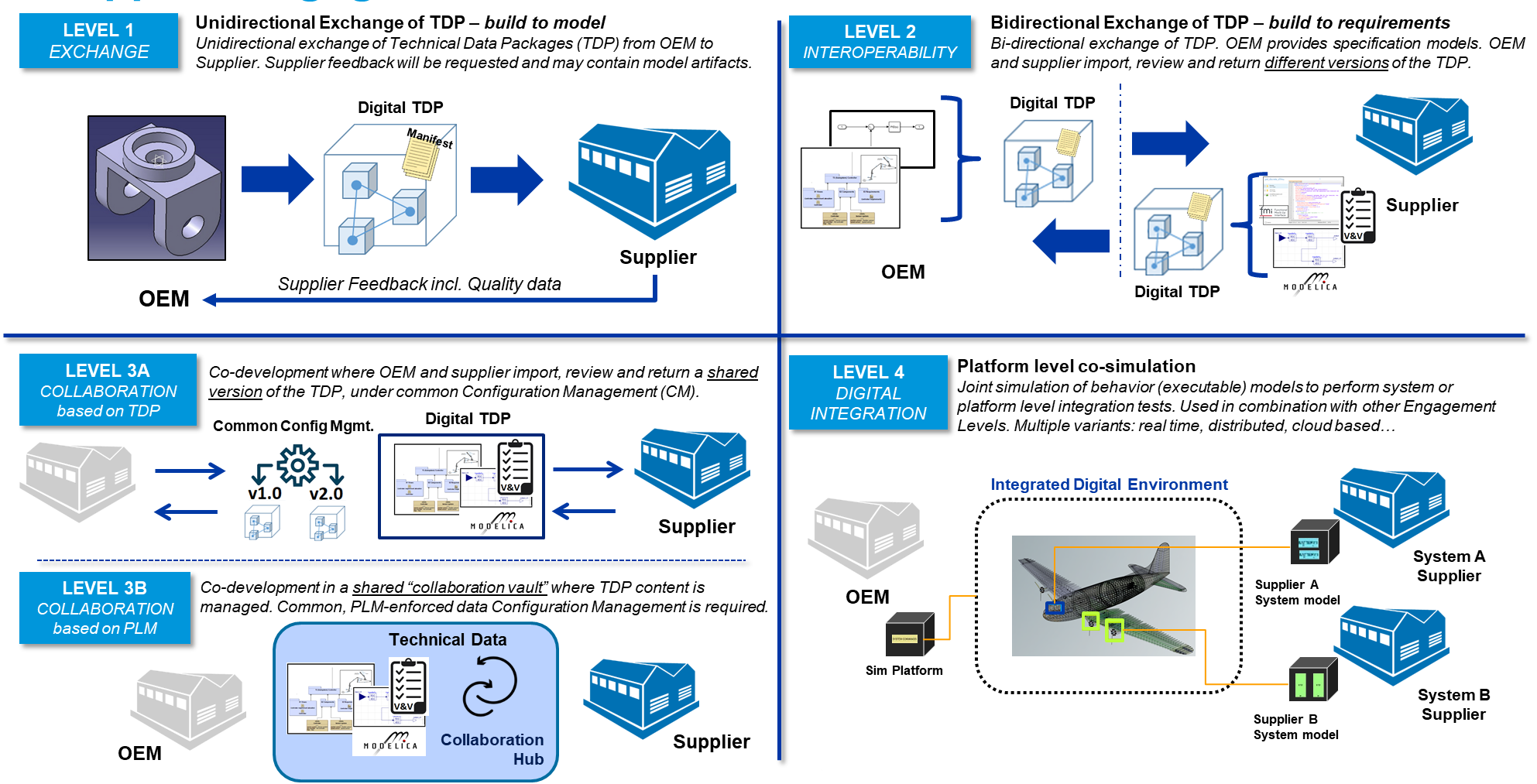

Example: Boeing Levels of Collaboration

Boeing for example defines four levels of collaboration in their Supplier Enablement Framework (SEF) as shown in Fig.7.

Fig.8: Boeing defines four levels of collaboration using a “Technical Data Package” (TDP). Source: Boeing Inc.

Fig.8: Boeing defines four levels of collaboration using a “Technical Data Package” (TDP). Source: Boeing Inc.

The four levels of collaboration are characterized as follows:

| Level 1 | Level 2 | Level 3A | Level 3B | Level 4 | |

|---|---|---|---|---|---|

| Title | Exchange | Interoperability | Collaboration based on TDP | Collaboration based on PLM | Digital Integration |

| Direction | to supplier | to and from supplier | to and from supplier | to and from supplier | to and from supplier |

| Configuration Management | no | no | yes | yes | yes |

| Data management | file exchange | file exchange | file exchange | PLM collaboration or independent hub | fully integrated |

| Collaboration Mode | 1 | 1 | 1 | 2 or 3 | 3 or 4 |

CASCaDE shall address all those levels and modes. The information model must hence support serialization in a container for ‘offline’ or ‘asynchronous’ working as well as transactions on entities and relations for ‘online’ or ‘synchronous’ working. Of course, the visibility and use of entities and relations is controlled by permissions per user role: Not everything is exposed to everyone.

Furthermore, work in parallel by different participants requires management of revisions at artifact level with branching and merging. Maintaining ‘working’ combinations of artifact revisions is commonly called configuration management. These operations are well understood by software development and deployment (often called ‘Application Lifecycle Management (ALM), but also by Product Lifecycle Management (PLM).

Please note that the name CDP has been chosen to show the succession of Technical Data Package (TDP) and Digital Data Package (DDP). While both TDP and DDP have contributed important capabilities in data exchange and collaboration in general, a solid foundation on existing OMG standards is missing. By applying formal methods to bridge technologies, interoperability will be greatly enhanced. The authors are well aware that the notion of ‘package’ in CDP may not adequately describe the more advanced collaboration modes as mentioned before.